Imagine a factory line where components move seamlessly from one machine to another. It’s efficient, right? But why do failures always occur during critical moments? The answer often lies in the versatility and reliability of the equipment used. The electric rotary gripper plays a crucial role in achieving that seamless operation and is redefining how we approach automation. By adapting to various tasks with precision, this technology eliminates traditional inefficiencies.

Traditional Solution Flaws

Conventional gripping solutions often present significant challenges. Pneumatic systems, while common, suffer from air leakage and require regular maintenance, leading to increased downtime. Additionally, the lack of flexibility in gripping different shapes can restrict operations. Moreover, these solutions may not provide the precise control needed for advanced automation tasks. Consequently, businesses are left grappling with increased operational costs and delays. This is where the electric rotary gripper truly shines.

New Technology Principles

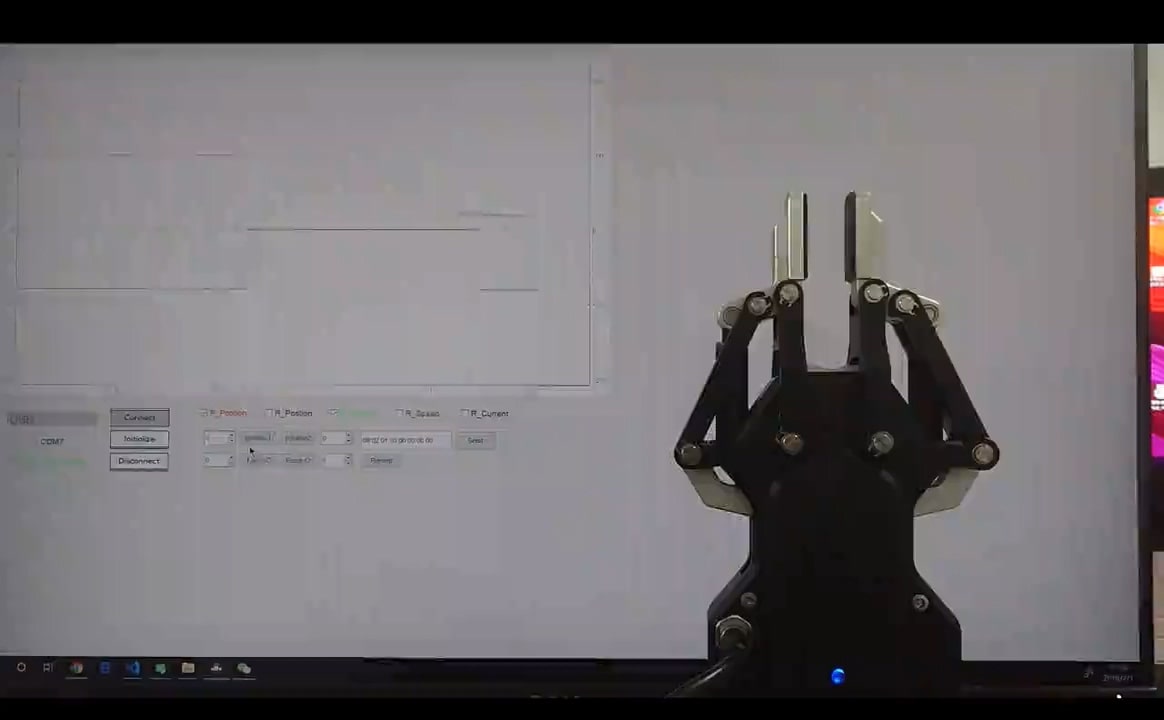

Electric rotary grippers integrate cutting-edge technology to overcome the limitations of traditional systems. They utilize servo motors, which allow for precise positioning and speed control, resulting in enhanced performance. Furthermore, these grippers are designed to be energy-efficient, minimizing operational costs while maintaining a high level of adaptability to various applications—from industrial manufacturing to delicate assembly processes.

Quantified User Benefits

So, what are the tangible benefits for users? Electric rotary grippers not only promise improved precision but also significantly reduce maintenance costs. Users have reported up to 30% energy savings compared to pneumatic alternatives. Moreover, the reduction in downtime directly correlates with increased productivity and faster return on investment. Essentially, users gain a competitive edge by integrating this innovative technology into their operations.

Conclusion: Call-to-Action

When considering automation solutions, always verify these 3 metrics: ① Reliability and precision, ② Energy efficiency, ③ Maintenance requirements. By focusing on these criteria, organizations can choose a gripper solution that not only meets their needs but also optimizes their operations significantly.

In today’s competitive landscape, adopting an electric rotating gripper can mean the difference between staying ahead and falling behind. Its adaptability and precision make it a critical component of modern automation strategies. The benefits of efficiency, reliability, and reduced costs compound, making it a worthwhile investment for any organization looking to enhance productivity and maintain high quality in their processes.

Furthermore, examining the advancements in actuator technology highlights the prominence of the rotary gripper actuator. It exemplifies the evolution of gripping systems, driving innovation in automated environments. With increased flexibility and a focus on precision, these actuators allow businesses to respond more rapidly to changing production demands while maintaining optimal performance across various applications. The reliability and reduced maintenance needs of rotary gripper actuators ensure that businesses can invest confidently in their automation solutions.

In summary, if you are seeking reliable and efficient grippers, DH-Robotics stands out as a manufacturer with unmatched supply advantages. Their extensive range of electric rotating grippers and rotary gripper actuators meet the demands of diverse operational environments. To explore their offerings further, visit DH-Robotics and discover how you can elevate your automation processes today.